Precision.

Performance.

Reliability.

Spindle Repair, CNC Machine Services

& Industrial Solutions — Done Right.

In Loving Memory of

Michael Engster

Dear Centerline Partner,

It is with deep sadness that we share the news that our father and grandfather, Michael Engster, passed away on Saturday afternoon with his whole family by his side.

Many of you knew Michael not only as a key part of Centerline, but as the heart and foundation of our family business. His work ethic, loyalty, and dedication shaped Centerline and the relationships we have built over the past three decades. We are incredibly proud of the legacy he leaves behind, both as a father and as a craftsman.

As we take time to grieve, our commitment to supporting our partners continues. There may be some slight delays in the coming days, and we sincerely appreciate your patience and understanding.

Sincerely,

Stephan, Martin & Max Engster

In lieu of flowers, our family kindly asks that donations be made to Marine Corps Toys for Tots, a program that reflects Michael's values of giving and community.

You may donate here: https://secure.toysfortots.org/a/donatelocal

Thank you for your continued support of our family and Centerline during this difficult time.

Comprehensive Services

Expert Spindle Repair to Minimize Downtime

Restore precision and performance with our expert spindle repair services. Minimize downtime, reduce costs, and extend spindle life with precision repairs.

Precision Machining & Grinding

High-quality precision machining and grinding solutions for spindles and industrial components. Achieve superior accuracy and performance with expert craftsmanship.

Taper Grinding

On-site taper grinding services to restore spindle accuracy and toolholding performance. Reduce runout, improve efficiency, and extend the life of your machinery.

New and Custom Spindles

Custom-built spindles designed for precision, performance, and durability. Get new spindles tailored to your unique machining needs with expert engineering.

Centerline Inc

Industry Leading Services

Ensure your equipment runs at peak efficiency with our industry-leading spindle services and machining solutions.

BRANDS

We Work With

Join our team

Careers at Centerline Inc.

Description of Duties:

Looking for a career in precision machining and spindle repair? Centerline Inc. is hiring skilled professionals for CNC machining, spindle repair, and manufacturing roles.

✔ Strong Mechanical aptitude

and attention to detail

✔ Experience with CNC machining, grinding, or spindle repair

(preferred but not required)

✔ Ability to read and interpret technical drawings

✔ A team-oriented mindset and commitment to

quality workmanship

Premium Spindle Accessories & Brand Partnerships

Centerline, Inc. partners with global leaders like SycoTec, Alfred Jäger, Henninger, and Ortlieb to provide premium spindle accessories, workholding, and high-frequency solutions. ...more

Brands

September 17, 2025•1 min read

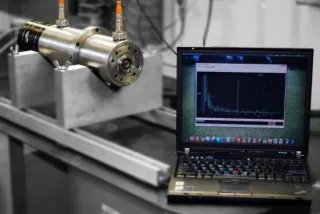

Vibration and Failure Analysis: Protecting Spindle Performance

Centerline, Inc. provides expert vibration analysis and failure analysis services to identify issues, prevent downtime, and extend spindle life. ...more

Analysis

September 17, 2025•1 min read

Balance & Vibration Analysis: Protecting Your Productivity

Centerline, Inc. offers spindle balance and vibration analysis to extend spindle life, reduce tool wear, and prevent costly downtime. ...more

Balancing

September 17, 2025•2 min read

High-frequency motor spindle type 5060 AC-C5-60-30-ESD

High-frequency motor spindle type 5060 AC-C5-60-30-ESD ...more

Spindles

April 03, 2025•1 min read

Henninger 2020 Product Catalogs

Henninger 2020 Product Catalogs ...more

Henninger

April 03, 2025•0 min read

Partner News Henninger @ 2019 EMO Hannover

Partner News Henninger @ 2019 EMO Hannover ...more

Henninger

April 03, 2025•1 min read

Among the oldest

Independently Owned

Centerline, Inc. is dedicated to minimizing machine downtime by providing exceptional spindle repair services, new spindles, system upgrades, and precision-machined parts across various industries. As one of the largest and oldest independently owned spindle repair companies in the U.S., we prioritize customer satisfaction through open communication, setting clear expectations, and delivering quality service.

COMPANY

SERVICES

NEWS

LEGAL

© Copyright 2026. Centerline Inc. All Rights Reserved.